CFA Piles Continuous Flight Auger Piles

1. Technology behind CFA piles

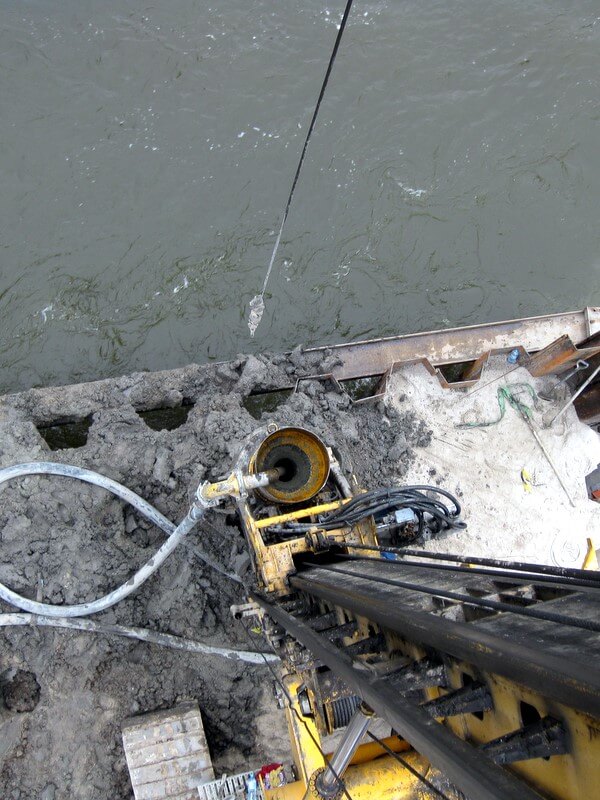

CFA Piles (Continuous Flight Auger) are drilled using a hollow shaft continuous flight auger.

Installing CFA piles involves drilling the auger to its final depth. Once the depth is reached, concrete mix is pumped into the auger’s hollow shaft knocking out the sacrificial shoe which sealed the auger tip. As the auger is withdrawn, concrete is pumped through the hollow shaft to the bottom of the CFA ensuring continuous support of the hole waals by the CFA pile.

After the auger is removed, reinforcement, prefabricated to specification, is inserted into the fluid concrete. The hollow shaft’s large diameter allows for inserting a reinforcement cage prior to concreting, which makes reinforcing long CFA piles much easier.

2. CFA pile use

CFA piles are predominantly used in stiff cohesive and dense non-cohesive soils. This technology is relatively cheap to install considering the usable load bearing capacity of the piles. An installation procedure which is vibration free makes it feasible to use in the proximity of other buildings.

3. CFA piles technical parameters (CFA piles load bearing/CFA piles diameters)

We install the following CFA Piles:

- diameters: ø300, ø400, ø500, ø600 mm

- maximum length: 30 m

- load bearing capacity: up to 2000 kN (soil conditions permitting)